by Lesley Day Mirling

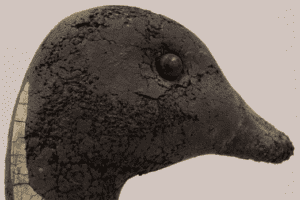

Over the course of the last year, I have examined and treated fifty-three of Shelburne Museum’s wildfowl decoys as part of a Samuel H. Kress Foundation Fellowship in Conservation (administered by the Foundation for the American Institute for Conservation). It has been fascinating to explore the wide range of materials that have been used in decoy making since the late 19th century. While the vast majority of the museum’s decoys are made of carved wood, other decoy materials in the collection include papier-mâché, canvas, fiberboard, bundled reeds, plastic, metal, and rubber. This pintail decoy, described in the museum’s collection database as being made of cellular rubber, was in particularly bad condition due to the active deterioration of its substrate material and could not be handled safely or displayed.

Many modern manufacturing materials that came into use in the 20th century such as plastic, rubber, and polyurethane foam are inherently unstable. Over time, these materials begin to actively deteriorate as their substituent components break down due to chemical processes that are catalyzed by exposure to the environment (including exposure to light, oxygen, pollutants, and moisture in the air). In instances where an object is self-destructing due to its inherent vice, often the best approach for preservation of the material is to remove destructive factors from its environment- i.e. put the object into dark, cold, dry, anoxic storage. This approach may prolong the life of the object, however, with the unfortunate trade-off that the object can no longer be viewed.

Cellular rubber (the material identified in object description) refers to rubber that has been manufactured with a foaming agent to create an air-filled matrix structure. Commercial foam rubbers are generally made from either latex or polyurethane, and this decoy was determined to be made of polyurethane foam based on its date and physical appearance. Unfortunately, there is not an easy solution to conserve polyurethane foams once the deterioration process has begun, however, recent promising research has investigated materials and methods that can extend the life of these materials.

Several options were weighed in consultation with curator Kory Roger s, including isolating the object from destructive environmental factors, and we decided to investigate treatment methods that would allow the object to remain on view because this decoy contributes to the history of innovations and inventions within the context of decoy making.

Consolidation tests were conducted on small crumbles of foam that had detached from the object using dilute adhesives that had been tested on deteriorating polyurethane foams with good results in accelerated aging studies.

In addition to testing different adhesives, two methods of adhesive application were also investigated. A nebulizer was used to apply the dilute adhesive in a fine mist and brush application was also tested. The advantage of using a nebulizer is that it allows the adhesive to be delivered in extremely fine aerosol droplets that coat the cell walls of the foam rather than filling them, which could cause the foam to become rigid.

Though using the nebulizer was fun, brush application of the adhesive was found to better penetrate the foam structure and prevent crumbling and surface losses. The chosen adhesive was applied carefully over the entire surface in several applications using a fine-tipped brush, delivering the adhesive into fine cracks, and surrounding crumbling surfaces.

The foam consolidation treatment has successfully stabilized and extended the exhibition life of the decoy which will be on view in climate-controlled visible storage under UV-filtered lighting when Dorset House reopens this fall.